Harrybilt Engineering

Ballast & Material Handling

Harrybilt Engineering manufacture high quality and extremely durable rail maintenance equipment for use on excavators or backhoes.

These attachments are fitted with a quick hitch and can be used with a tilt rotating head for maximum flexibility and maneuverability.

Products

Remove excess ballast

Ballast Sweeper

The Ballast Sweeper has been designed by Harrybilt Engineering to remove excess ballast from the rail line and sleeper clips.

Undercutter / Ballast Remover

Centipede

A time saver for any rail maintenance team, the Centipede - Undercutter / Ballast Remover removes spoil fast and without fuss.

Ideal for railway maintenance

Cribbing Bucket

Harrybilt Engineering’s Cribbing Bucket is ideal for railway maintenance.

Ideal for cleaning up ballast

Excavator Grading Blade

The Harrybilt Engineering Grading Blade is suitable for both Civil and Rail applications, making jobs much quicker and more efficient.

Ballast Compaction

Tamper No 2

The No. 2 unit (medium 4 leg) is particularly suitable for use on backhoes and 10-14 tonne excavators.

Ballast Compaction

Tamper No 3

The No.3 unit (large 4 leg) is particularly suitable for use on 14-18 ton excavators.

Ballast Compaction

Tamper No 2 - Light Weight

The light weight Tamper No. 2 is suitable for 5-10 ton excavators.

Ballast Compaction

Twin Tamper 2

Twin Tamper models are available to suit machines from a backhoe to large excavators.

Ballast Compaction

Twin Tamper 3

Twin Tamper models are available to suit machines from a backhoe to large excavators.

Ballast Compaction

Twin Tamper No 2 - Light Weight

Twin Tamper models are available to suit machines from a backhoe to large excavators.

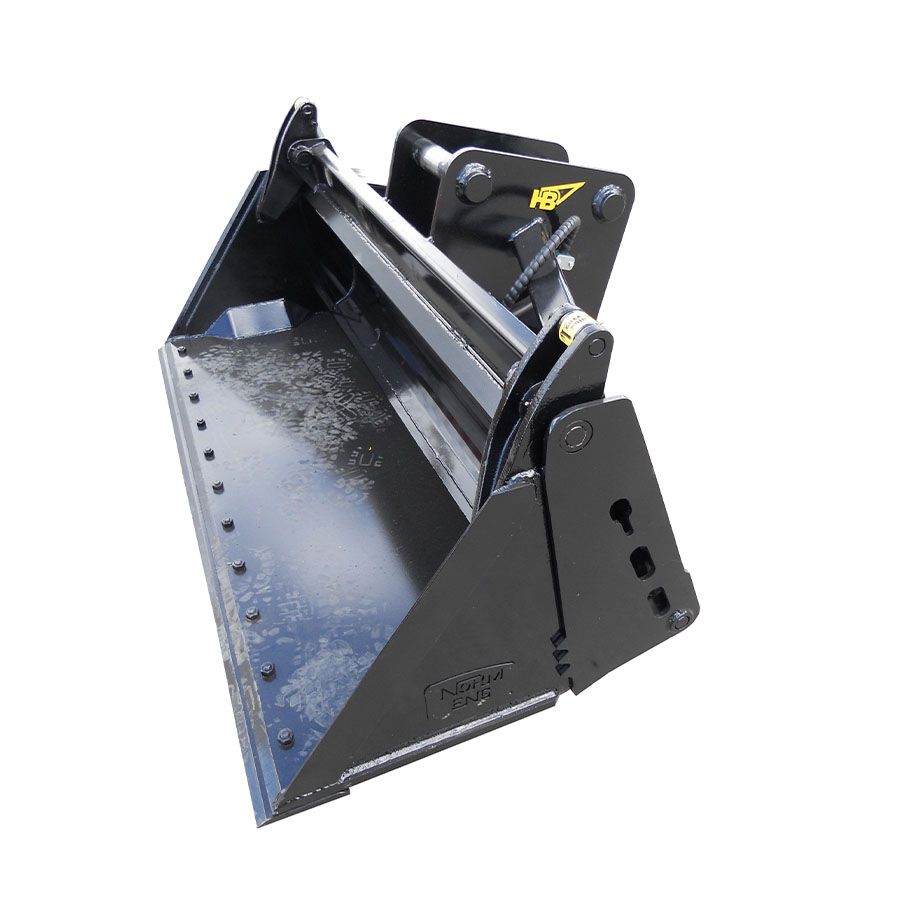

Loading and Unloading Material

4in1 Bucket

Harrybilt Engineering’s 4in1 Bucket is designed for loading and unloading material such as ballast and shaping the formation shoulders.

Material Handling

Buckets

Harrybilt Engineering can supply buckets and fit with a quick hitch to suit customer requirements.

Raking and Cleaning

Rake / Blade Combo

Our new Rake / Blade attachment has a twin position hitch so that the operator is able to pick up the attachment for raking or cleaning up with the blade edge.

Like to find out more about our products?

If you're interested in discovering more about any of our products, you can download a copy of any of our brochures here in PDF format. These brochures contains additional product details and specifications that you may find helpful. For any further enquiries, please don't hesitate to contact us.